With Radioss, explicit simulation and nonlinear dynamic analysis become decisive tools for developing safer, stronger, and higher-performing products.

Its versatility and ability to handle complex scenarios make Radioss a strategic ally across technology-intensive industries.

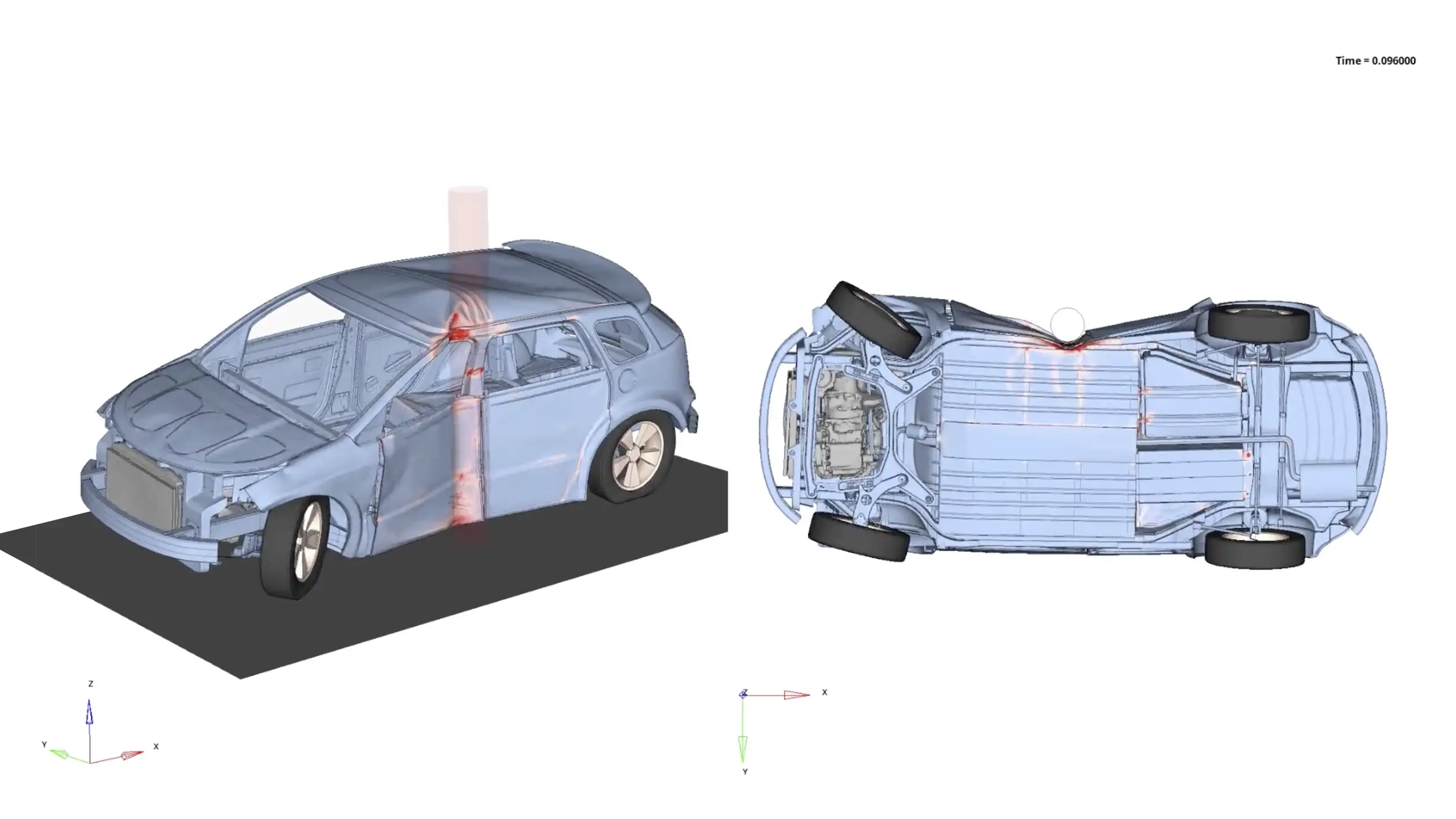

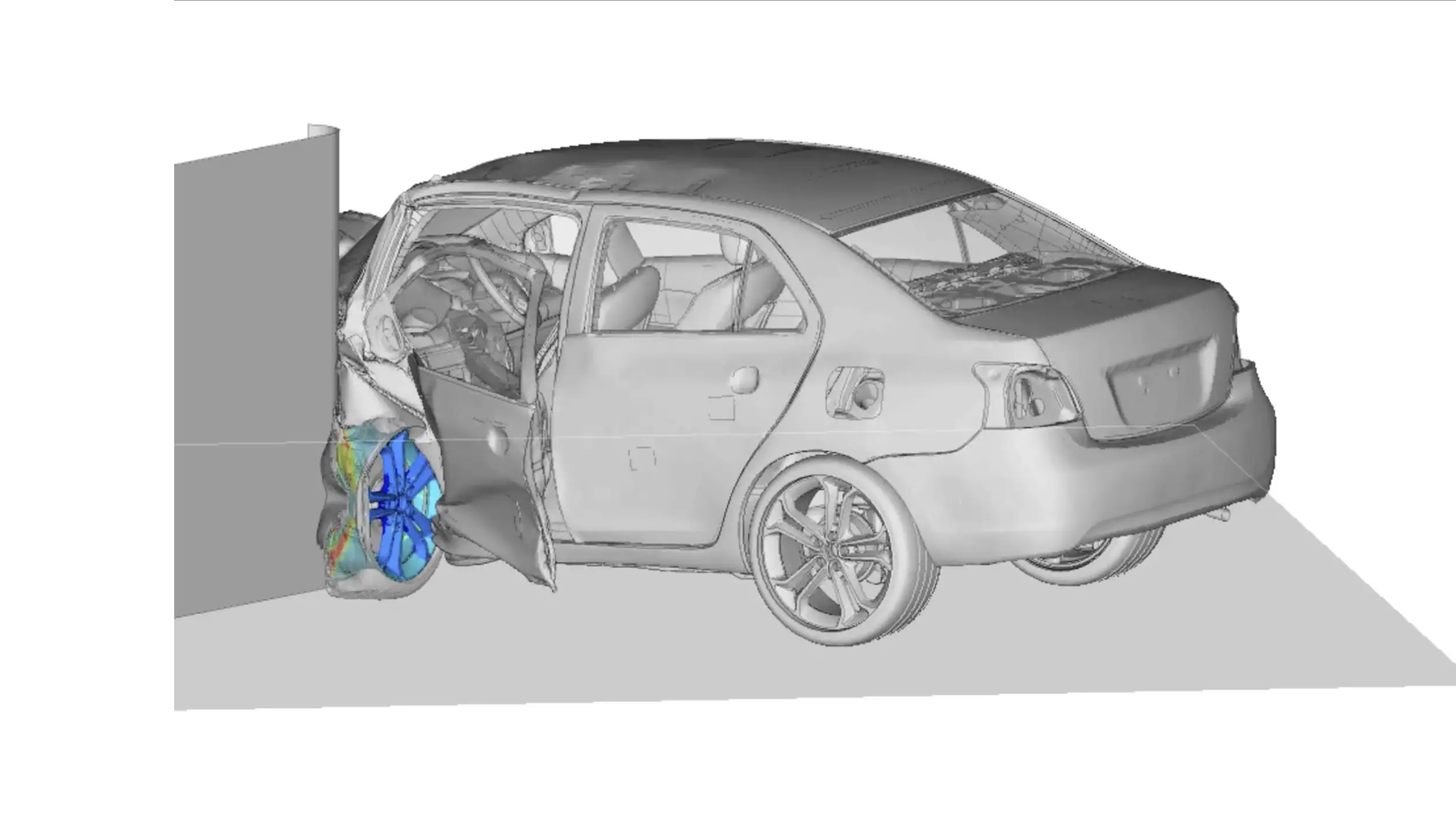

Crash and Passive Safety

Radioss is a proven platform for crash test simulation, safety analysis, and structural optimization in the transportation sector.

Its technology enables the analysis of complex scenarios such as full-vehicle crashes, high-speed impacts, and rollovers.

It is a fundamental tool for regulatory validation and enhancement of passive safety, thanks to its ability to handle detailed material and failure models.

Radioss also supports emerging applications like electric vehicle battery analysis and novel structural configurations for urban air mobility.

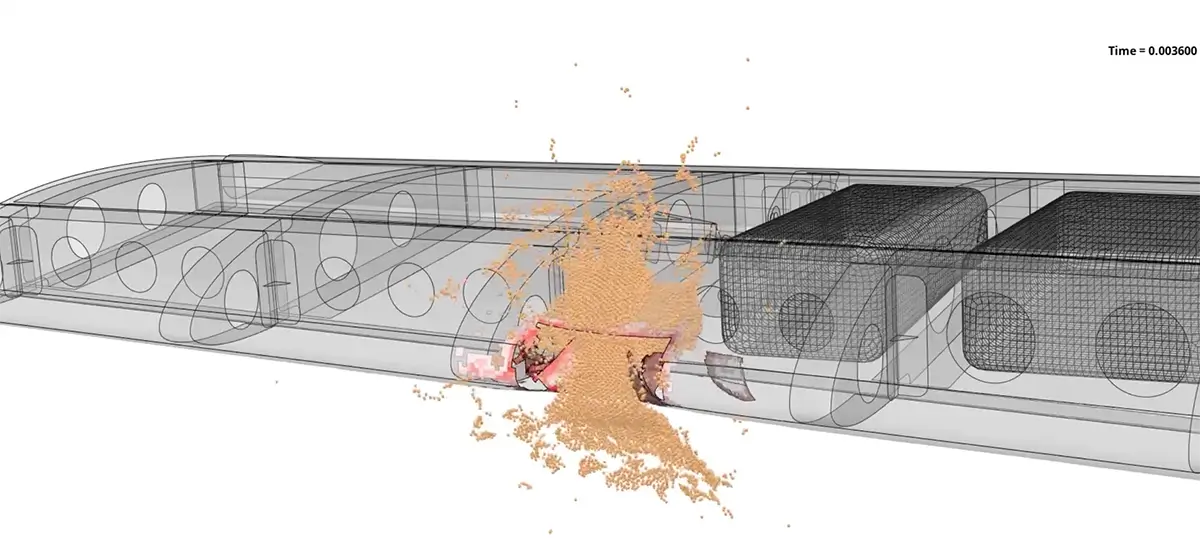

High-Velocity Dynamic Events

Radioss plays a critical role in ensuring the reliability of mission-critical structures, enabling realistic simulation of extreme events such as bird strikes, jet engine blade containment, and sudden component failure.

Its advanced capabilities in composite material modeling help optimize both strength and weight.

The accuracy of its validated models makes Radioss ideal for aerospace applications, where structural safety is paramount.

Explosions and Ballistic Impacts

Originally developed to meet defense sector demands, Radioss is now a mature tool for simulating high-energy events such as explosions and ballistic impacts.

With advanced numerical techniques like Arbitrary Lagrangian-Eulerian (ALE) and Smoothed Particle Hydrodynamics (SPH), it enables detailed analysis of fluid-structure interactions in highly complex scenarios.

Radioss is widely used in the design and validation of protective systems, military equipment, and critical infrastructure in civil applications.

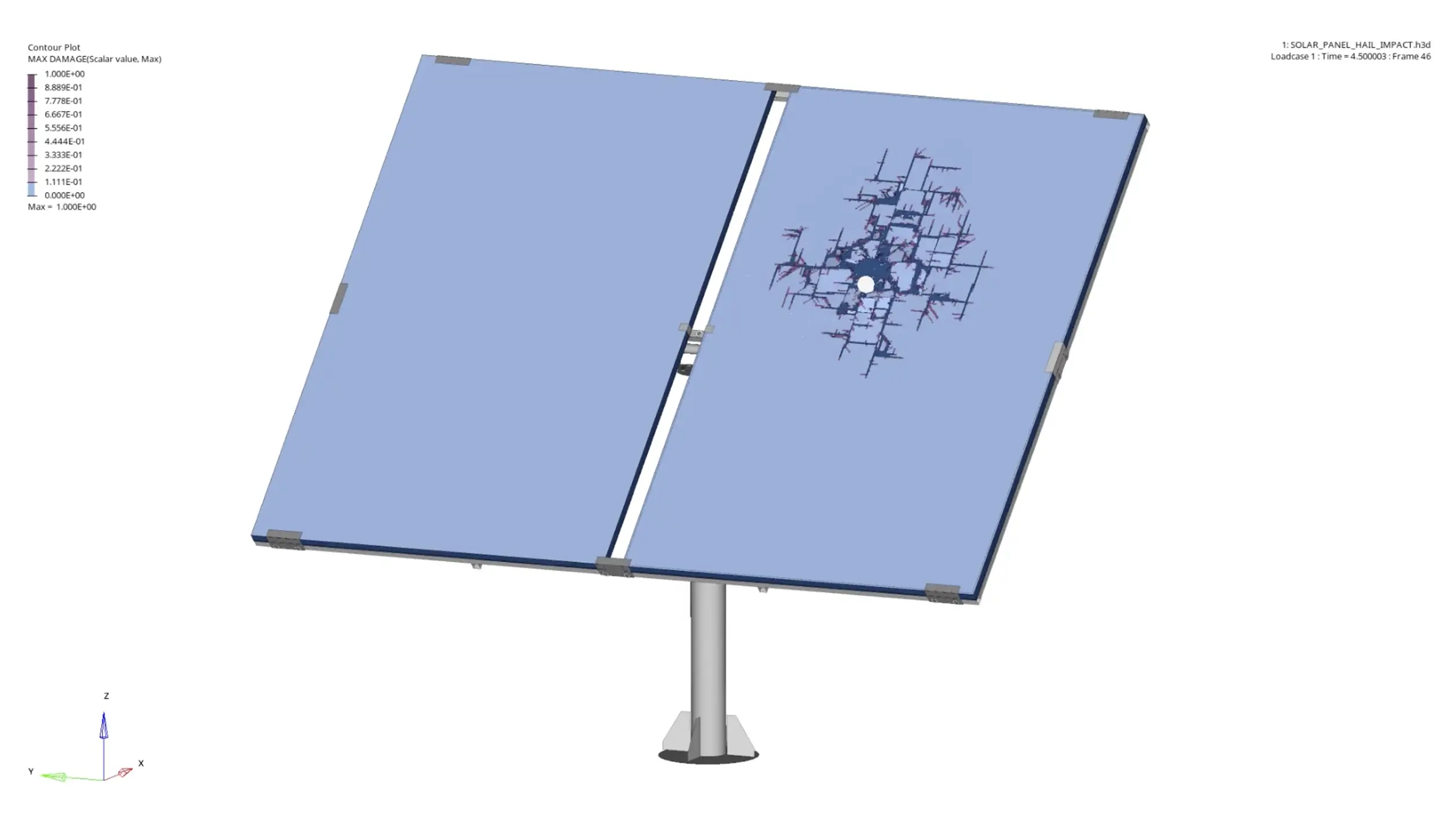

Energy Applications and Extreme Environments

In the energy sector, Radioss is employed to design systems that must operate reliably under extreme environmental conditions.

It can simulate seismic events, dynamic loads, or climate-related phenomena such as hail impact on exposed surfaces.

It is used in the development and validation of offshore platforms, renewable energy infrastructure, and components exposed to accelerated environmental wear.

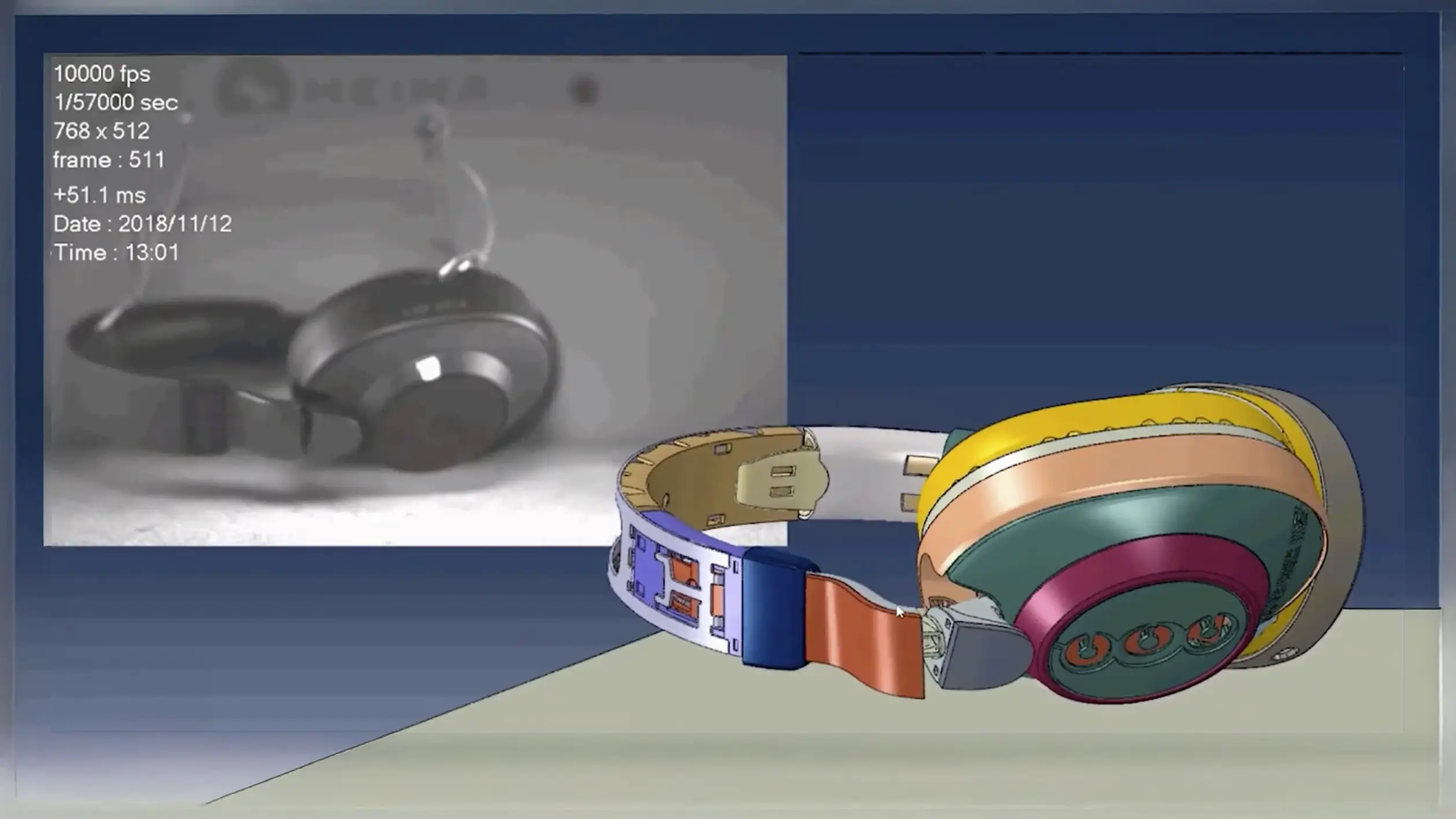

Electronics, Drop Testing, and Impact Analysis

Radioss enables detailed evaluation of products subjected to accidental impacts or unconventional use conditions.

It is an effective tool for simulating drops, shocks, and deformations on electronic and mechanical devices, anticipating failure risks on displays, enclosures, batteries, and packaging.

Advanced modeling of materials such as technical fabrics, rubbers, and foams allows engineers to optimize comfort, durability, and injury protection.

Advanced Materials and Fluid-Structure Interaction

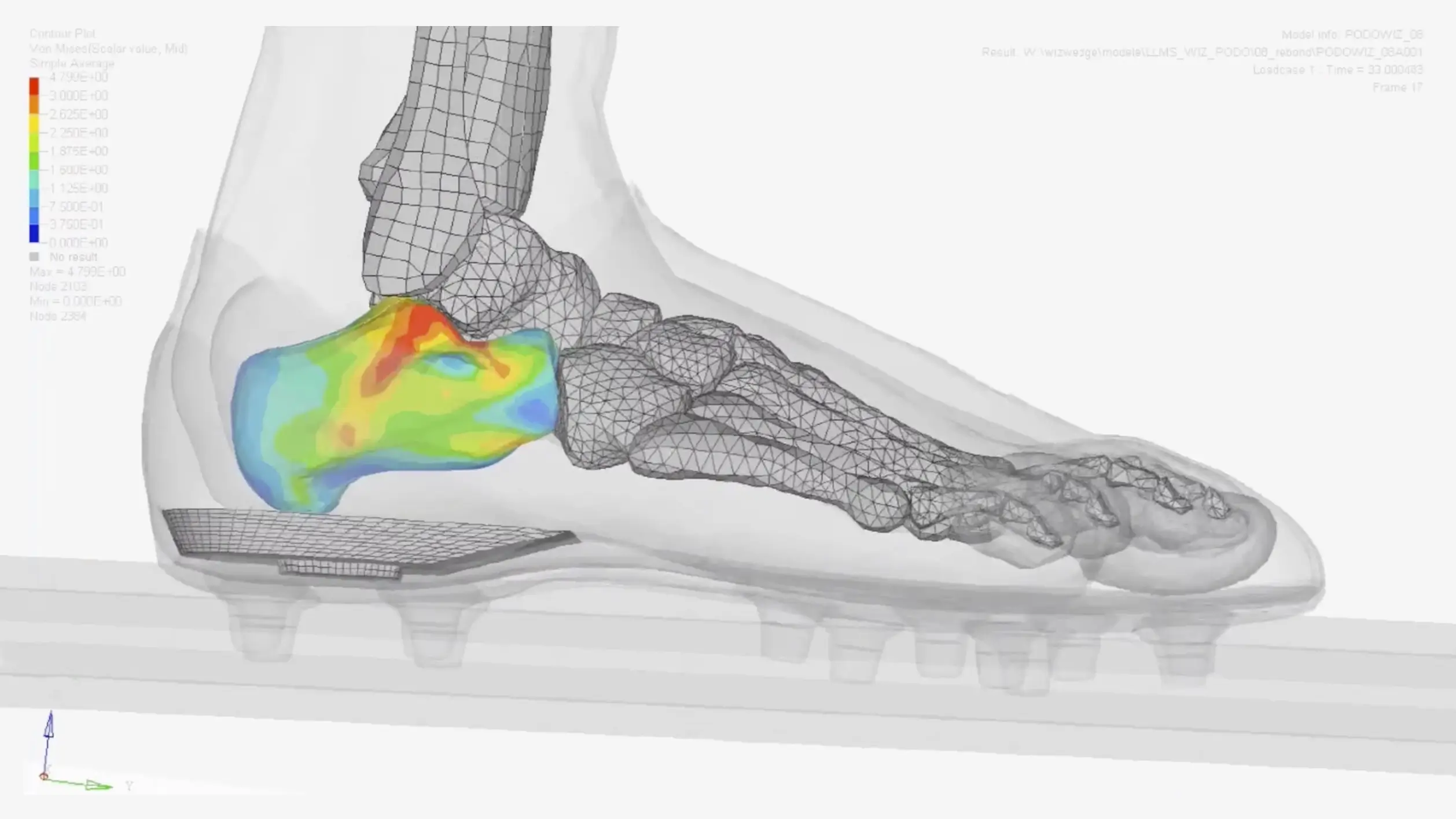

Radioss excels at simulating the nonlinear behavior of materials, even under large deformations, making it ideal for analyzing flexible and complex structures.

It is particularly effective when fluid-structure interaction is a key factor in system performance.

Applications include custom medical devices, wearable technologies, biomechanical systems, and engineered components that require a balance between flexibility and dynamic responsiveness.

Innovation That Drives Better Design

Integrating Radioss into engineering workflows accelerates innovation, reduces the cost of physical prototyping, and enables the development of higher-performing products.

It is a mature yet continuously evolving technology, ready to meet the engineering challenges of today and tomorrow.

Request the Radioss trial now

Try Radioss, a powerful, scalable and integrable solution to anticipate issues and optimize the performance of your projects.